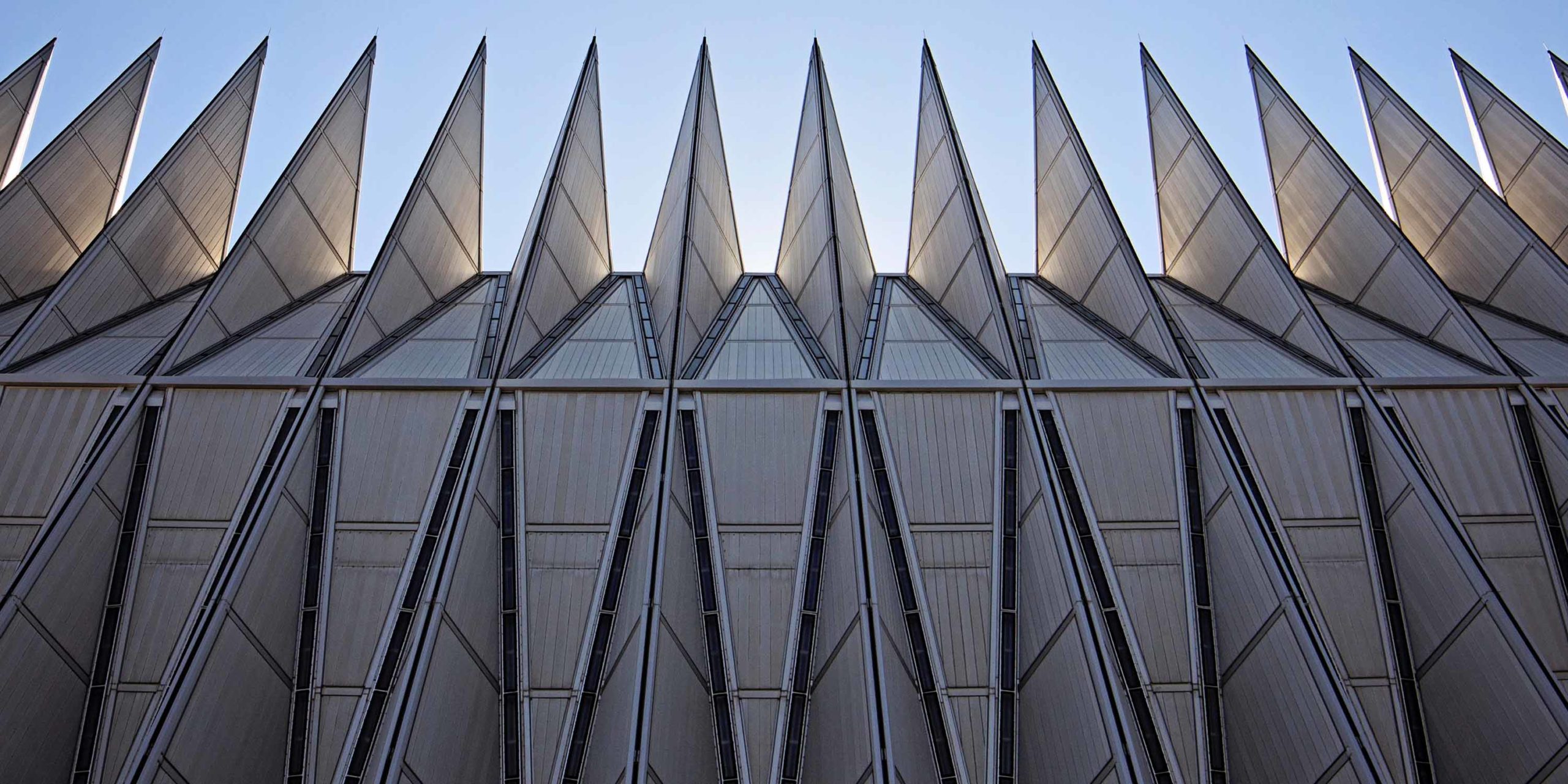

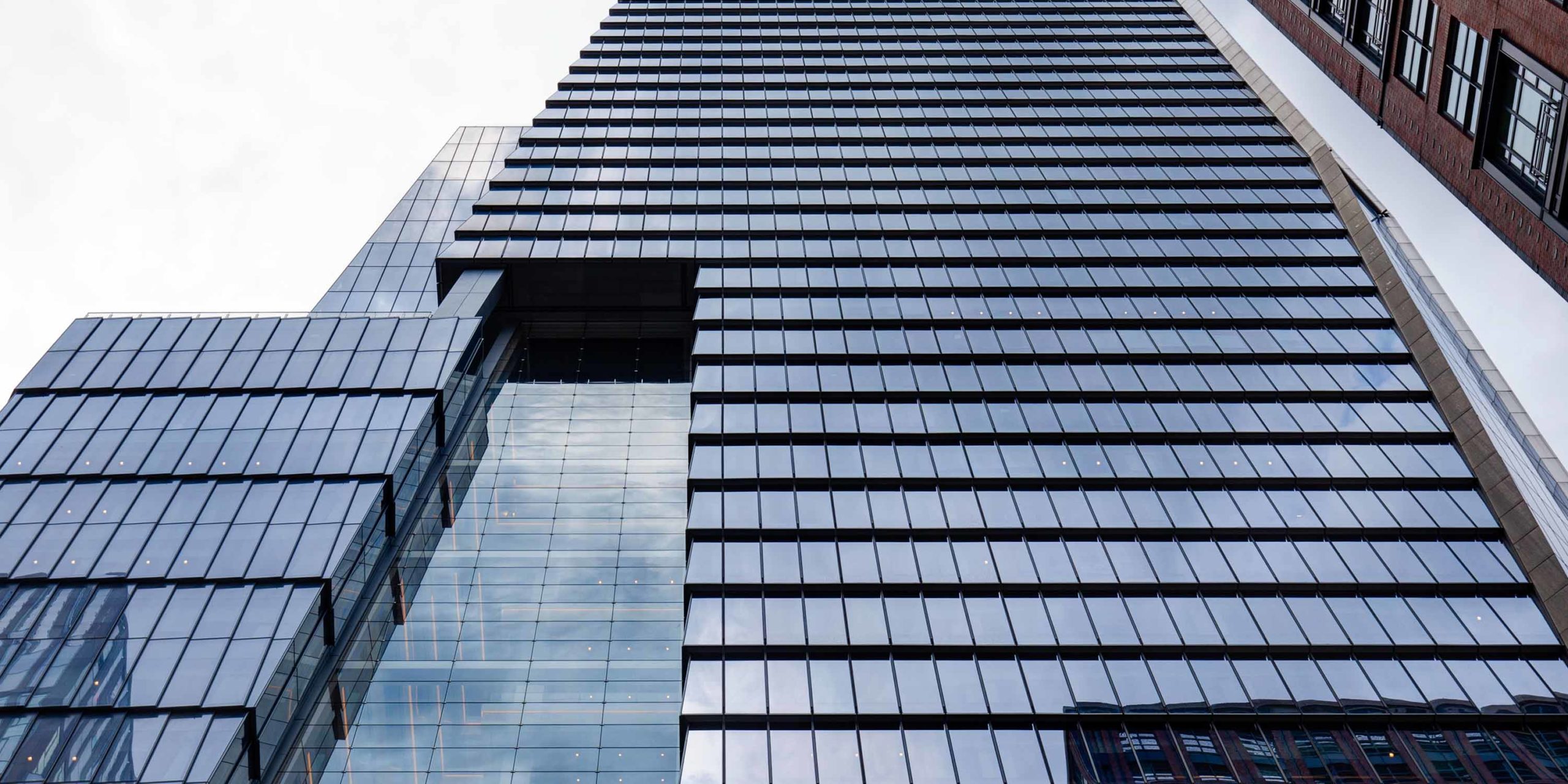

The direct lineage of Enclos dates to the beginning of curtainwall as a building form in the mid-20th century. As one of the first companies active in this new marketplace, Enclos has played a leading role in developing this technology through the years into the refined, high-performance curtainwall systems of today. For decades we have built our reputation on professionalism, quality, honesty, integrity, and ingenuity.

Operating under various brand names (Cupples, Harmon Ltd., Harmon Contract, Enclos Corp.), and mergers, one thing has remained constant: our team is committed to pioneering the course of advanced building enclosures.

1918

THE HALLIDIE BUILDING

WHAT MADE CURTAINWALL POSSIBLE?

William Jenney’s introduction of a steel framing for load-bearing components of structure spawned new possibilities for skyscrapers (late 19th c)

The nation’s first glass curtain wall was built in San Francisco in 1918, the Hallidie Building.

1946

CUPPLES PRODUCTS IS FORMED

1952

Lever House in Midtown Manhattan is first building in New York to feature a curtainwall

1954

Cupples’ first curtainwall: Webb and Knapp Tower, New York Beginning of Cupple’s relationship with I.M. Pei